What we can manufacture

Rubber Products

Our Production Lines

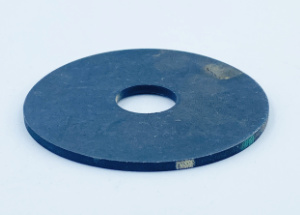

SQUARE RING SEALS

Rubber cut seals. We are one of the largest rubber lathe cut seal manufacturers in Mexico.

compression

We have injection and compression process of rubber diaphragms, seals, dust covers, etc.

Extrusion

Extruded profiles are manufactured for filters, car bodies, automotive industries, etc.

PLASTICS

We have new plastic injection lines at the Monterrey plant.

We manufacture millions of rubber seals per year.

SQUARE SECTION GASKETS and stamps cut from rubber. We are leaders in the manufacture of Square rings seals through the process known as “Lathe cut”, complying with a wide range of material specifications, dimensions, and tolerances, based on international standards such as ASTM, SAE, JIS, VDA, RMA, etc. They are manufactured with a wide variety of elastomers, which allows us to cover a varied sector of industries that require excellent sealing.

PROJECT DEVELOPMENT FROM THE BOTTOM:

Compound development

Tooling Design

Large-scale production

Rubber injection

and compression

We have a diversity of presses with multiple injection capacities, which allows us to offer a wide range of solid rubber products at highly competitive prices.

The variety in dimensions in our presses gives us the ability to manufacture solid and sponge rubber products in all sizes and shapes to meet your sealing requirements. In addition, we have our own mold designing and manufacturing department, which gives us the necessary support to offer a comprehensive service and a better response to your needs.

We manufacture diaphragms, grommets, seals for water conduction, insulating caps, dust covers, etc. Made of Nitrile, SBR, Silicon, etc.

The variety in dimensions in our presses gives us the ability to manufacture solid and sponge rubber products in all sizes and shapes to meet your sealing requirements. In addition, we have our own mold designing and manufacturing department, which gives us the necessary support to offer a comprehensive service and a better response to your needs.

We manufacture diaphragms, grommets, seals for water conduction, insulating caps, dust covers, etc. Made of Nitrile, SBR, Silicon, etc.

MOLDS AND TOOLING SELF DESIGNED

In our mechanical workshop, we can prototype, design, and manufacture our own tooling based on the needs of our customers and engineering specifications.

Continuous vulcanization process

Extruded profiles are manufactured for the filter industry, car bodies, automotive, etc. In dense materials, sponges, flock, double hardness, metal insert, silicone, etc.

The importance of the sealing against water, air, noise, and dust in the interior of the cars, is totally covered with our extensive catalog of extruded profiles vulcanized in a continuous way, manufactured in dense rubber, sponge rubber, and co-extrusion and with Teflon and polyester flock coatings.

4 LINES OF CONTINUOUS VULCANIZATION

We have four CV lines at our Monterrey plant, where we can produce extruded profiles for different types of industries.

DEVELOPMENTS

Plastic injection lines

Plastics are another sealing option, they provide us multiple choices in a wide variety of molded pieces, in different colors and hardnesses ranging from grommets to seals for panel-type filters in automotive’s air conditioning.

NEW DIVISION OF PLASTICS

Since 2018 we have started the development of plastic injection products at the Monterrey plant, and we already have an installed capacity to develop our projects in this area.